Concrete screws, also known as masonry screws, are one of the most essential fasteners used in construction and DIY projects. They provide a secure and reliable method to anchor objects into concrete, brick, or block surfaces. Whether you're a professional contractor or a homeowner looking to tackle your next project, understanding the right type of concrete screw to use is crucial for achieving long-lasting results.

When it comes to construction materials, concrete screws are often overlooked despite their importance. They are specifically designed to withstand the rigors of heavy-duty applications, ensuring that whatever you attach to concrete remains firmly in place. Proper selection and installation of these screws can significantly enhance the safety and durability of your projects.

This comprehensive guide will walk you through everything you need to know about concrete screws, from their types and applications to installation tips and best practices. By the end of this article, you'll have the confidence and knowledge to choose the right product for your needs.

Read also:What Is Rick Bayless Net Worth 2024 Wealth Insights And Financial Journey

Table of Contents

- Introduction to Concrete Screws

- Types of Concrete Screws

- Applications of Concrete Screws

- Materials Used in Concrete Screws

- Understanding Concrete Screw Sizes

- How to Install Concrete Screws

- Tools Needed for Installation

- Installation Tips and Tricks

- Maintenance and Longevity

- Frequently Asked Questions

Introduction to Concrete Screws

What Are Concrete Screws?

Concrete screws are specialized fasteners designed to anchor materials into hard surfaces such as concrete, brick, or block. Unlike traditional wood screws, concrete screws are made from durable materials that can penetrate and grip into masonry surfaces without cracking or damaging them.

These screws are typically made from stainless steel or carbon steel with a zinc coating to prevent rust and corrosion. Their unique threading design allows them to bite into concrete, creating a strong and secure hold. This makes them ideal for both indoor and outdoor applications, especially in environments exposed to moisture or weather conditions.

One of the key benefits of using concrete screws is their versatility. They can be used to attach a wide range of materials, including metal, wood, and plastic, to concrete surfaces. Whether you're installing shelves, mounting a TV, or securing heavy equipment, concrete screws provide a reliable solution.

Types of Concrete Screws

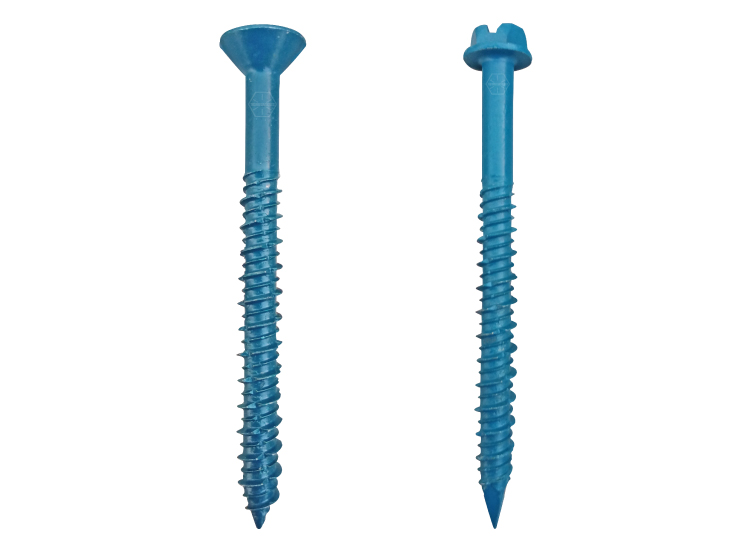

Blue Concrete Screws

Blue concrete screws are made from carbon steel with a blue phosphate coating. They are affordable and widely used for general-purpose applications. However, they are not recommended for outdoor use due to their susceptibility to rust.

Stainless Steel Concrete Screws

Stainless steel concrete screws are corrosion-resistant and ideal for outdoor applications. They are more expensive than blue screws but offer superior durability and longevity. These screws are commonly used in coastal areas or environments where moisture is a concern.

Self-Tapping Concrete Screws

Self-tapping concrete screws have sharp threads that cut into concrete without the need for pre-drilling. This feature makes installation faster and easier, especially for smaller projects. However, they may not be suitable for very hard surfaces.

Read also:What Is Abdullah The Butcher Net Worth 2024 Career Achievements And Wealth

Applications of Concrete Screws

Concrete screws are incredibly versatile and can be used in a variety of applications. Some common uses include:

- Installing shelves and cabinets

- Mounting signs and fixtures

- Securing fences and gates

- Attaching machinery and equipment

- Building decks and patios

When selecting concrete screws for a specific application, consider factors such as the weight of the object being attached, the type of surface, and environmental conditions. Choosing the right screw will ensure optimal performance and longevity.

Materials Used in Concrete Screws

The material of a concrete screw plays a significant role in its performance and durability. Here are the most common materials used:

- Carbon Steel: Economical and widely available, but prone to rust.

- Stainless Steel: Corrosion-resistant and suitable for outdoor use.

- Zinc-Coated Steel: Offers moderate corrosion resistance at a lower cost.

Each material has its own advantages and disadvantages, so it's important to choose based on the specific requirements of your project.

Understanding Concrete Screw Sizes

Concrete screws come in various sizes, measured by diameter and length. The size you choose will depend on the thickness of the material being attached and the depth of the concrete surface. Here's a breakdown of common sizes:

- Diameter: Ranges from 3mm to 6mm.

- Length: Typically available in increments of 25mm, with lengths ranging from 25mm to 150mm.

As a general rule, the screw should penetrate at least 25mm into the concrete for optimal holding power. Always consult the manufacturer's guidelines for specific recommendations.

How to Install Concrete Screws

Step-by-Step Guide

Installing concrete screws is a straightforward process, but attention to detail is crucial for achieving a secure hold. Follow these steps for successful installation:

- Mark the location where you want to place the screw.

- Drill a pilot hole slightly larger than the screw diameter.

- Insert the concrete screw into the hole.

- Tighten the screw using a power drill or screwdriver until it is snug.

Remember to use the appropriate drill bit and ensure the pilot hole is deep enough to accommodate the screw length.

Tools Needed for Installation

To install concrete screws effectively, you'll need the following tools:

- Hammer drill

- Masonry drill bit

- Power drill or screwdriver

- Measuring tape

- Marker

Having the right tools will make the installation process smoother and more efficient. It's also important to wear safety gear, such as goggles and gloves, to protect yourself during drilling.

Installation Tips and Tricks

Here are some additional tips to help you achieve the best results when installing concrete screws:

- Always clean the pilot hole to remove debris before inserting the screw.

- Do not overtighten the screw, as this can cause it to strip or break.

- Use a depth gauge to ensure consistent hole depth for multiple screws.

- Consider using anchor adhesive for extra strength in critical applications.

These tips will help you avoid common mistakes and ensure a secure installation every time.

Maintenance and Longevity

To maximize the lifespan of your concrete screws, proper maintenance is essential. Regularly inspect the screws for signs of rust or damage, especially in outdoor applications. If rust is present, remove it using a wire brush and apply a rust-inhibiting coating.

For long-term durability, consider using stainless steel screws in high-moisture environments. They offer superior resistance to corrosion and can last for many years with minimal maintenance.

Frequently Asked Questions

1. Can concrete screws be used in wet environments?

Yes, but it's recommended to use stainless steel or zinc-coated screws to prevent rust and corrosion.

2. How deep should a concrete screw be inserted?

As a general guideline, the screw should penetrate at least 25mm into the concrete for optimal holding power.

3. Can I use concrete screws in brick or block?

Absolutely! Concrete screws are designed to work with a variety of masonry materials, including brick and block.

4. What happens if I overtighten a concrete screw?

Overtightening can cause the screw to strip or break, compromising its holding power. Always tighten screws until they are snug, but avoid excessive force.

5. How do I remove a concrete screw?

To remove a concrete screw, use a power drill in reverse mode or a screw extractor. Be cautious not to damage the surrounding surface during removal.

Conclusion

Concrete screws are an indispensable tool for anyone working with masonry surfaces. By understanding their types, applications, and installation techniques, you can ensure successful and secure anchoring for all your projects. Remember to choose the right screw for your specific needs and follow best practices for installation and maintenance.

We encourage you to share your experiences with concrete screws in the comments below. Have you encountered any challenges during installation? What tips do you have for fellow DIY enthusiasts? Your feedback helps us create better content for our readers.

Don't forget to explore our other articles on construction tools and techniques. Knowledge is power, and with the right information, you can tackle any project with confidence!